Understanding Progressive Die Manufacturing

What is a Progressive Die?

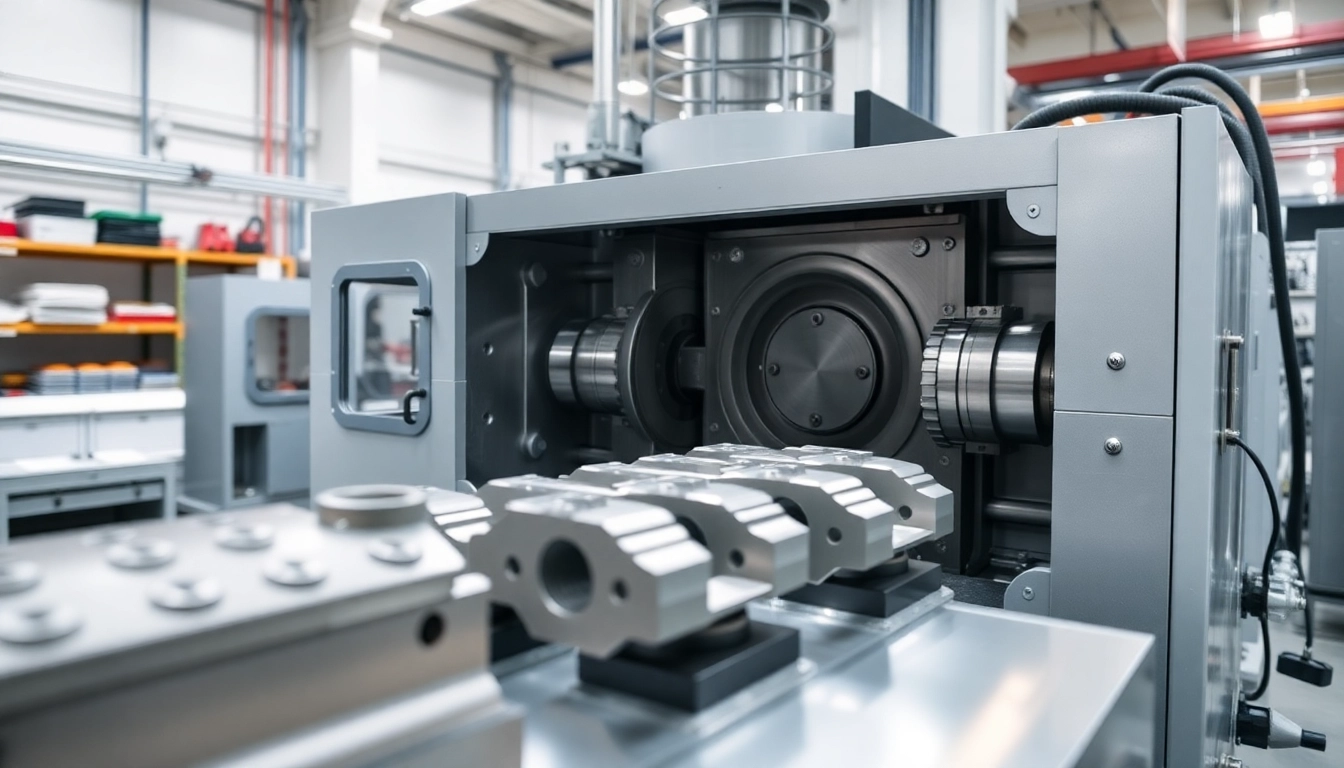

A progressive die is a specialized tool used in manufacturing processes to create multiple parts through a single stroke of a press machine. The design of a progressive die allows for sequential operations, meaning that as the material is fed through the die, various forming, cutting, and shaping actions take place simultaneously across different stations of the die. This method is particularly beneficial for high-volume production, as it streamlines processes by eliminating the need for multiple setups.

The high demand for efficiency and precision manufacturing has propelled the use of Progressive Die technologies across industries. With advancements in technology and materials, modern progressive dies are capable of producing intricate designs and complicated geometries, thus meeting the varied needs of manufacturers.

Key Features of Progressive Dies

Progressive dies have several key features that contribute to their effectiveness in manufacturing:

- Sequential Operations: Each stroke of the press carries the workpiece through multiple operations, such as cutting and bending, occurring in different die stations.

- Automation Friendly: Progressive die design often integrates seamlessly with automated systems, enhancing productivity and reducing manual labor.

- Material Efficiency: The process minimizes waste material, as the blank is fully utilized in the stampings.

- Complex Geometry Capable: Designed to produce complex, high-precision parts that would be challenging to achieve with traditional methods.

- High Repetition Accuracy: Ensures consistency across all produced parts, crucial for industries needing precise specifications.

Advantages of Using Progressive Dies

The benefits of utilizing progressive dies in manufacturing are numerous:

- Cost-Effective Production: Ideal for high-volume runs, progressive dies reduce per-piece manufacturing costs significantly.

- Time Efficiency: By combining multiple operations in a single die, the production cycle is shortened, making it possible to meet tight deadlines.

- Improved Product Quality: The inherent design precision of progressive dies leads to superior product reliability and performance.

- Reduced Labor Requirements: Automation integrated into the production process minimizes the need for manual intervention, allowing skilled labor to focus on more complex tasks.

The Progressive Die Design Process

Steps in Designing a Progressive Die

The design of progressive dies involves several critical steps to achieve optimal functionality:

- Concept Development: Define the part requirements and functionalities based on customer specifications or design requirements.

- Preliminary Design: Create initial sketches or CAD models to visualize the die structure and functionality.

- Material Selection: Choose appropriate materials for both the die and the parts being manufactured, ensuring compatibility and durability.

- Prototype Testing: Develop prototypes to test the die’s performance in real conditions, allowing for adjustments and iterations.

- Final Design Approval: Complete the design with final adjustments and obtain stakeholder approval before mass production.

Materials Used in Progressive Die Production

Choosing the right materials is essential for the effectiveness of progressive dies:

- Tool Steel: Used for its hardness and wear resistance, making it ideal for high-impact applications.

- Stainless Steel: Excellent for applications requiring corrosion resistance.

- Aluminum: Lightweight and easy to machine, favored in less demanding applications.

- Carbide: Selected for its extreme hardness, perfect for high-friction applications in die tooling.

Common Challenges and Solutions

Despite their advantages, the use of progressive dies in manufacturing can present certain challenges, including:

- Tool Wear: Frequent use can lead to rapid wear. To combat this, heat treatments and coatings can extend die life.

- Material Limitations: Some materials may not be suitable for stamping. Testing and modifying the raw materials can help solve this issue.

- Complex Design Requirements: As designs become more intricate, producing the dies requires advanced engineering, often necessitating 3D models and simulations.

Applications of Progressive Dies in Industries

Automotive Industry Applications

Progressive dies play a pivotal role in the automotive sector, where they are used to manufacture components like brackets, clips, and intricate chassis parts with precision. They help produce lightweight parts that can withstand rigorous driving conditions, thereby optimizing vehicle performance and safety.

Aerospace and Defense Applications

In aerospace and defense, progressive dies are employed to manufacture aircraft components and military equipment parts. Their ability to produce complex shapes with tight tolerances is vital for enhancing the durability and reliability of these critical applications.

Electronics Manufacturing Applications

The electronics industry utilizes progressive dies for producing metal housings, connectors, and components that require high precision. As electronic devices become smaller and more intricate, the need for sophisticated progressive die technology becomes increasingly relevant.

Quality Control in Progressive Die Manufacturing

Importance of Quality Assurance

Quality assurance is paramount in the manufacturing of progressive dies as it directly influences the performance and longevity of the dies and their produced parts. A robust QA process helps in identifying defects early in the production cycle, reducing waste, and ensuring the final product meets all specifications.

Tools and Technologies for Quality Control

Several tools and technologies are adopted to uphold quality in progressive die manufacturing:

- Coordinate Measuring Machines (CMM): Provide precise measurements of parts to ensure dimensional accuracy.

- Laser Scanning: Used for 3D part inspections to detect discrepancies in the design.

- Statistical Process Control (SPC): Monitors production processes in real-time, aiding in the prompt identification of quality issues.

Case Studies of Successful Implementation

Numerous companies have successfully implemented progressive die technology to streamline their production processes. For instance, an automotive manufacturer doubled production efficiency after integrating progressive die systems into their manufacturing line, showcasing the tangible benefits of this technology in delivering cost reductions and enhanced production timelines.

Future Trends in Progressive Die Manufacturing

Innovations in Die Technology

The future of progressive die manufacturing is driven by technological innovations such as additive manufacturing, which allows for the creation of complex die geometries that traditional methods find challenging. Furthermore, advancements in simulation tools improve design accuracy and reduce development times.

Sustainability in Die Fabrication

As industries increasingly focus on sustainability, progressive die manufacturing is evolving. Material recycling and utilizing eco-friendly materials where possible will become prevalent practices in die production.

The Impact of Automation on Progressive Dies

Automation continues to revolutionize manufacturing, and progressive dies are not exempt. With the integration of robotics and artificial intelligence, manufacturers can expect enhanced production capabilities, reducing lead times and improving overall workflow efficiencies. This potential for increased production efficiency, coupled with reduced labor costs, positions progressive dies favorably for future market needs.