Understanding Redditch Powder Coating

When it comes to the world of surface finishing, redditch powder coating stands out as a robust and versatile option. Utilized in various industries, powder coating offers an aesthetic enhancement alongside vital protection for metal surfaces. In this article, we will delve into the intricacies of powder coating, exploring its definitions, benefits, applications across different sectors, and the specific services available in Redditch.

What is Powder Coating?

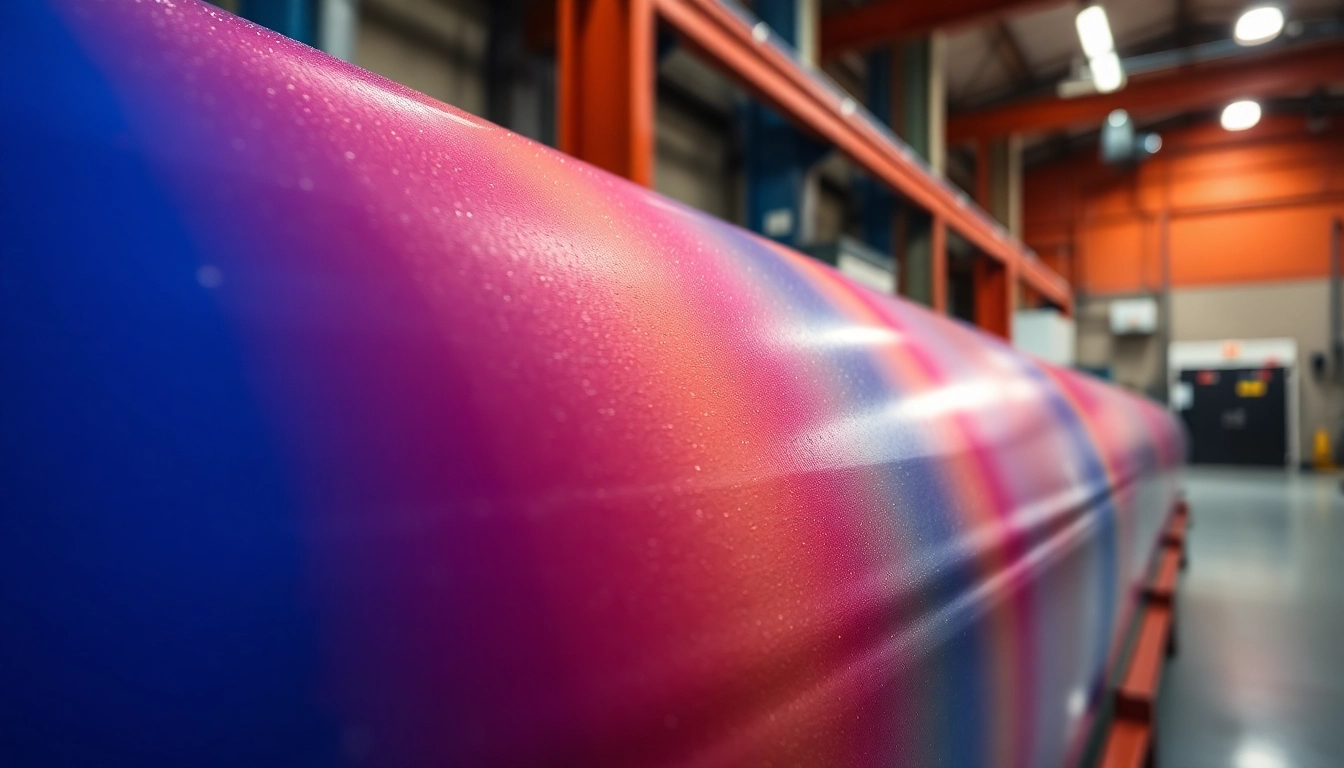

Powder coating is a dry finishing process that employs a free-flowing, dry powder. When sprayed onto a surface, typically metal, it is electrically charged and adheres seamlessly. This application is followed by curing under heat, which causes the powder to melt and form a hard, protective layer. The process is distinct from traditional liquid paint, leveraging advanced technologies to create coatings that are durable and aesthetically pleasing.

Benefits of Using Powder Coating

Powder coating offers numerous advantages, making it a preferred choice for various applications. Key benefits include:

- Durability: Powder coatings are highly resistant to chipping, scratching, fading, and wearing compared to liquid paint.

- Environmentally Friendly: Unlike traditional coatings, powder coatings emit no volatile organic compounds (VOCs), making them safer for the environment.

- Cost-Effective: Due to minimal overspray and the ability to reclaim unused powder, the overall costs can be lower.

- Aesthetic Variety: Powder coating is available in a vast array of colors and textures, providing endless possibilities for design.

- Corrosion Resistance: It provides a protective barrier, reducing the likelihood of rust and corrosion, especially in outdoor applications.

Applications of Powder Coating in Various Industries

Powder coating is used extensively in numerous industries, including:

- Automotive: Enhances durability and appearance of automotive parts such as wheels, frames, and trims.

- Furniture: Ideal for metal furniture, providing a long-lasting and visually appealing finish.

- Architectural: Used for window frames, railings, and building exteriors to ensure long-term protection against the elements.

- Sports Equipment: Coating for bicycles and gym equipment ensures longevity and aesthetics.

- Electronics: Often utilized for electronic housings where heat resistance and aesthetic appeal are critical.

Choosing the Right Powder Coating Services in Redditch

As demand for powder coating services in Redditch grows, finding the right company to meet your specific needs becomes essential. Here are some considerations that can help you make an informed choice.

Key Factors to Consider When Selecting a Service

- Experience: Evaluate the company’s history and years of experience in powder coating.

- Quality of Work: Review portfolios and client testimonials to gauge the quality of previous work.

- Technical Capabilities: Ensure the company has the necessary equipment and expertise to handle your specific project.

- Customer Service: Consider how responsive and supportive they are during your initial inquiries.

- Environmental Standards: Check if they adhere to environmental practices in their finishing process.

Comparing Local Redditch Powder Coating Providers

When comparing local providers such as Alpha of Redditch and Washford Finishings, consider factors like pricing, turnaround times, and service offerings. Many of these providers specialize in diverse aspects of powder coating, which may include

- Custom color matching

- High-volume production runs

- Specialized equipment for specific applications

Researching local reviews and requesting quotes from multiple vendors can ensure competitive pricing and quality service.

Questions to Ask Your Powder Coating Partner

Before finalizing a partnership with a coating provider, here are a few critical questions to consider:

- What materials do you coat?

- What is the typical turnaround time for projects?

- Are you using environmentally friendly materials?

- What is your warranty policy on finished products?

- Can you provide examples of past projects similar to mine?

The Powder Coating Process Explained

Understanding the powder coating process can help clients appreciate the complexity and precision involved in achieving high-quality finishes.

Preparation Steps Before Coating

The preparation of the substrate is critical to the success of powder coating. This phase usually includes:

- Cleaning: Items must be thoroughly cleaned to remove any grease, contaminants, or rust.

- Surface Profiling: The surface is often textured to enhance adhesion; this can include sandblasting or grinding.

- Pre-Treatment: Applying a conversion coating (like phosphate) can enhance corrosion resistance.

Application Techniques and Equipment

Once preparation is complete, the actual application can begin. The typical methods include:

- Electrostatic Spray: The most common method where an electric charge is applied to the powder particles causing them to adhere to the grounded surface.

- Fluidized Bed Coating: In this method, the item is heated before being dipped into fluidized powder, which adheres smoothly and evenly.

Curing and Finishing Touches

The curing stage is vital—it involves using an oven to heat the coated items, allowing the powder to melt and chemically bond to the substrate. The curing time and temperature significantly influence the hardness and durability of the coating. Following curing, finishing touches may involve:

- Inspection for flaws or defects

- Touch-ups if necessary

- Packaging for delivery

Common Issues and Solutions in Redditch Powder Coating

Even with its many benefits, challenges can arise during the powder coating process. Knowing these problems and how to address them is essential for successful outcomes.

Identifying Incomplete Coverage Problems

One of the most common issues is incomplete coverage on complex shapes or intricate designs. This can usually be traced back to:

- Improper application technique or lack of electrostatic attraction.

- The equipment not being properly calibrated or maintained.

To remedy this, ensuring thorough technician training and strict maintenance schedules for equipment can significantly reduce the possibility of such issues.

Preventing Defects in the Coating Process

Defects such as orange peel, bubbling, or uneven texture can occur due to various factors, including:

- Inconsistent curing temperatures.

- Improper application thickness.

- Inadequate surface preparation.

Regular audits of the surface prep process, application settings, and curing profiles can help prevent such defects.

Ensuring Quality Control and Consistency

Implementing strict quality control measures, such as:

- Visual inspections at various stages

- Adherence to established processes

- Material traceability

These can help maintain consistent quality across all production runs and minimize discrepancies.

Getting Started with Your Powder Coating Project

Embarking on a powder coating project may seem daunting, but going through structured phases can facilitate a smooth process. Below are crucial steps to kick-start your project.

Initial Consultation and Quotation Process

A thorough initial consultation is vital where you can discuss your needs, specifications, and expectations. During this phase, a reputable service provider should evaluate the items and provide a detailed quotation, covering aspects like:

- Pricing per item

- Estimated timelines

- Potential additional costs for preparation or repairs

Preparing Your Items for Powder Coating

Your items will need adequate preparation before handing them off to the powder coating facility. This may include:

- Ensuring items are clean, dry, and free of any attachments or pieces that could interfere with the coating process.

- Providing any specifications or design considerations to your powder coating partner.

Follow-Up and Maintenance After Coating

Post-project follow-up is just as important. After coating, discuss the following with your service provider:

- Care instructions to maintain the finish over time.

- Warranties provided, if any, on the work.

- Options for future repairs or recoating if necessary.

By following these guidelines and understanding the intricacies of the redditch powder coating process, you can ensure that your coatings are performed to a high standard, offering both aesthetic value and protection for your metal items.