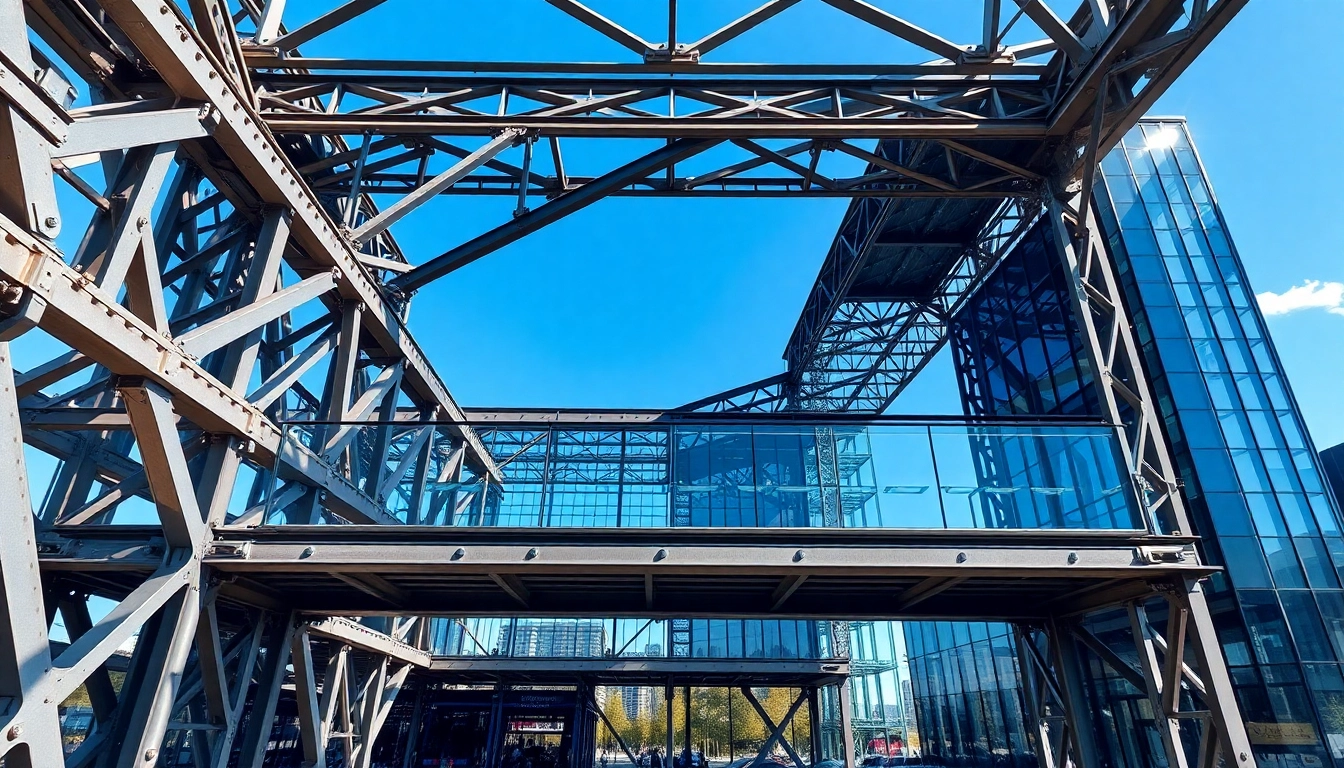

Understanding the Basics of Steel Structure Design

Steel structure design is an essential aspect of modern architecture and engineering, forming the backbone of countless commercial, residential, and industrial buildings. It involves systematically planning and engineering steel frameworks that can support various loads while ensuring safety, stability, and longevity. In essence, steel structure design combines artistic vision with engineering principles, resulting in structures that are not only functional but also aesthetically appealing. By familiarizing oneself with the fundamental principles and practices, designers can optimize their projects for durability and performance. For more information on the nuances of steel structure design, this article provides a comprehensive overview.

What is Steel Structure Design?

Steel structure design refers to the process of creating structural systems utilizing steel as the primary material. The process encompasses various phases, including conceptual design, structural analysis, detailing, and fabrication. Architects and engineers must consider factors such as load requirements, environmental conditions, and aesthetic objectives to ensure that the end product meets both functional and aesthetic needs. Steel is favored in structural design due to its remarkable properties, such as high tensile strength, versatility, and resistance to adverse environmental conditions.

Benefits of Using Steel in Structural Design

The use of steel in structural design comes with a plethora of advantages. These benefits include:

- High Strength-to-Weight Ratio: Steel offers exceptional strength, allowing for lighter structures that require less foundation support.

- Durability: Steel resists corrosion when properly treated and maintained, ensuring long-lasting performance even in harsh conditions.

- Flexibility: Steel can be molded into various shapes and sizes, offering architects the freedom to design innovative and unique structures.

- Speed of Construction: Pre-fabricated steel components can reduce construction time significantly, enhancing project efficiency.

- Cost-Effectiveness: Although initial costs can be higher, steel’s durability and reduced maintenance needs often lead to lower overall lifecycle costs.

Key Components of Steel Structures

Understanding the key components of steel structures is crucial for effective design. Major components include:

- Beams: Horizontal structures that support loads, transferring them to columns.

- Columns: Vertical members that carry the weight of beams and the structure above.

- Trusses: Frameworks of beams that provide support across large spans.

- Connections: Elements used to join different parts of steel structure, ensuring stability and integrity.

- Girders: Primary horizontal supports that connect columns and bear loads from beams.

Structural Analysis in Steel Structure Design

Structural analysis is a fundamental part of steel structure design. It entails examining mechanical properties and assessing the ability of a structure to withstand various forces

Principles of Structural Engineering

Structural engineering principles guide the design and analysis of structures to ensure they can support intended loads without failure. Key principles include:

- Equilibrium: Structures must maintain balance, meaning the sum of forces and moments acting on a system should be zero.

- Load Paths: Understanding how loads travel through a structure informs design considerations and materials selection.

- Safety Factors: Designing with safety margins to handle unforeseen loads or conditions enhances structural reliability.

Load Types and Distribution in Steel Design

Loads acting on steel structures can be broadly categorized into various types, each affecting design strategies:

- Dead Loads: Permanent forces such as the weight of the structure itself and non-movable fixtures.

- Live Loads: Temporary forces from occupants, furniture, and equipment that fluctuate over time.

- Environmental Loads: Forces resulting from environmental factors like wind, snow, and seismic activity.

Calculating these loads and understanding how they distribute across structural components is vital for ensuring strength and safety.

Software Tools for Structural Analysis

Modern structural engineers utilize advanced software for analysis and design purposes. Popular tools include:

- AutoCAD: For drafting detailed structural plans and designs.

- SAP2000: Widely used for structural analysis and design, especially for complex structures.

- ETABS: Specifically designed for building analysis and design, focusing on multi-story structures.

- STAAD.Pro: A versatile software that allows for the analysis and design of various types of structures.

Best Practices for Steel Structure Design

Adhering to best practices in steel structure design enhances safety, efficiency, and sustainability. Below are some key considerations:

Material Selection and Quality Assurance

Selecting appropriate materials is critical to the overall performance of steel structures. Quality assurance practices involve:

- Material Standards: Adhering to recognized standards such as ASTM and ISO for steel production ensures reliability.

- Testing: Conducting tests to assess material properties, including tensile strength and corrosion resistance, is vital.

- Regular Inspections: Ongoing inspections during the manufacturing and construction phases help identify potential defects early.

Sustainability Considerations in Steel Structure Design

As environmental concerns grow, the incorporation of sustainable practices in design is paramount. Strategies include:

- Recyclability: Steel is highly recyclable, aiding in reducing landfill waste.

- Energy Efficiency: Using energy-efficient practices in production and construction minimizes environmental impact.

- Design for Durability: Prioritizing longevity in design reduces the need for future resources and maintenance.

Compliance with Building Codes

A crucial aspect of steel structure design is ensuring compliance with local and national building codes. These codes dictate:

- Safety Standards: Requirements to ensure structural integrity and occupant safety.

- Design Loads: Minimum load requirements that structures must withstand.

- Accessibility Guidelines: Ensuring structures are accessible to all individuals, including those with disabilities.

Innovative Technologies in Steel Structure Design

As technology evolves, new methodologies and tools are increasingly shaping steel structure design. Below are noteworthy advancements:

Integrating BIM in Steel Construction

Building Information Modeling (BIM) is revolutionizing design processes by allowing for:

- Collaborative Design: Architects, engineers, and contractors can collaborate in real-time, improving communication and reducing errors.

- Visualization: Enhanced 3D models provide clear insights into how components fit together.

- Lifecycle Management: BIM facilitates ongoing management and maintenance of structures throughout their lifespan.

Advances in Steel Fabrication Techniques

Modern fabrication techniques enhance precision and efficiency in steel structures:

- Automated Cutting and Welding: Reducing human error and increasing consistency in fabrication.

- Modular Fabrication: Building pre-fabricated modules off-site can streamline construction processes and minimize on-site disruptions.

- 3D Printing: Emerging as a method for rapid prototyping and fabrication of complex steel components.

Connection Types and Their Impact on Design

Connections play a pivotal role in the stability and performance of steel structures. Key types include:

- Welded Connections: Providing a strong bond between steel members, suitable for high-stress applications.

- Bolt Connections: Allowing for quick assembly and disassembly, often used in modular designs.

- Moment Connections: Critical for structural stability, these connections help resist lateral forces.

Future Trends in Steel Structure Design

The future of steel structure design is being shaped by ongoing advancements, and upcoming trends are largely defined by technology, sustainability, and innovation. Key emerging trends include:

The Role of Automation in Steel Design

Automation is quickly becoming a critical player in the field. This encompasses:

- Automated Design Software: Tools that optimize structural designs based on parameters set by the designer, enhancing efficiency.

- Robotic Construction: Utilizing robotics for repetitive tasks in fabrication and assembly, increasing precision and safety.

- Data Analytics: Leveraging data to inform design choices and anticipate structural needs, improving overall performance.

Modular Steel Structures and Efficiency

Modular design approaches are gaining traction, allowing for:

- Easier Scalability: Modular constructions can be expanded or reduced with minimal disruption.

- Improved Quality Control: Off-site fabrication leads to better material handling and quality assurance.

- Faster Construction Times: Pre-fabricated modules can be quickly assembled on-site, reducing project timelines.

The Impact of Environmental Concerns on Design Choices

Environmental issues are making a significant impact on design choices within the steel structure industry. Engineers and architects must:

- Embrace Sustainable Materials: Utilizing recycled or sustainable steel products wherever possible.

- Incorporate Energy-Efficient Designs: Designing for optimal natural lighting and energy use reduces overall environmental impact.

- Stay Informed on Regulations: Remaining up-to-date with changing building regulations regarding sustainability helps in compliant and forward-thinking design.