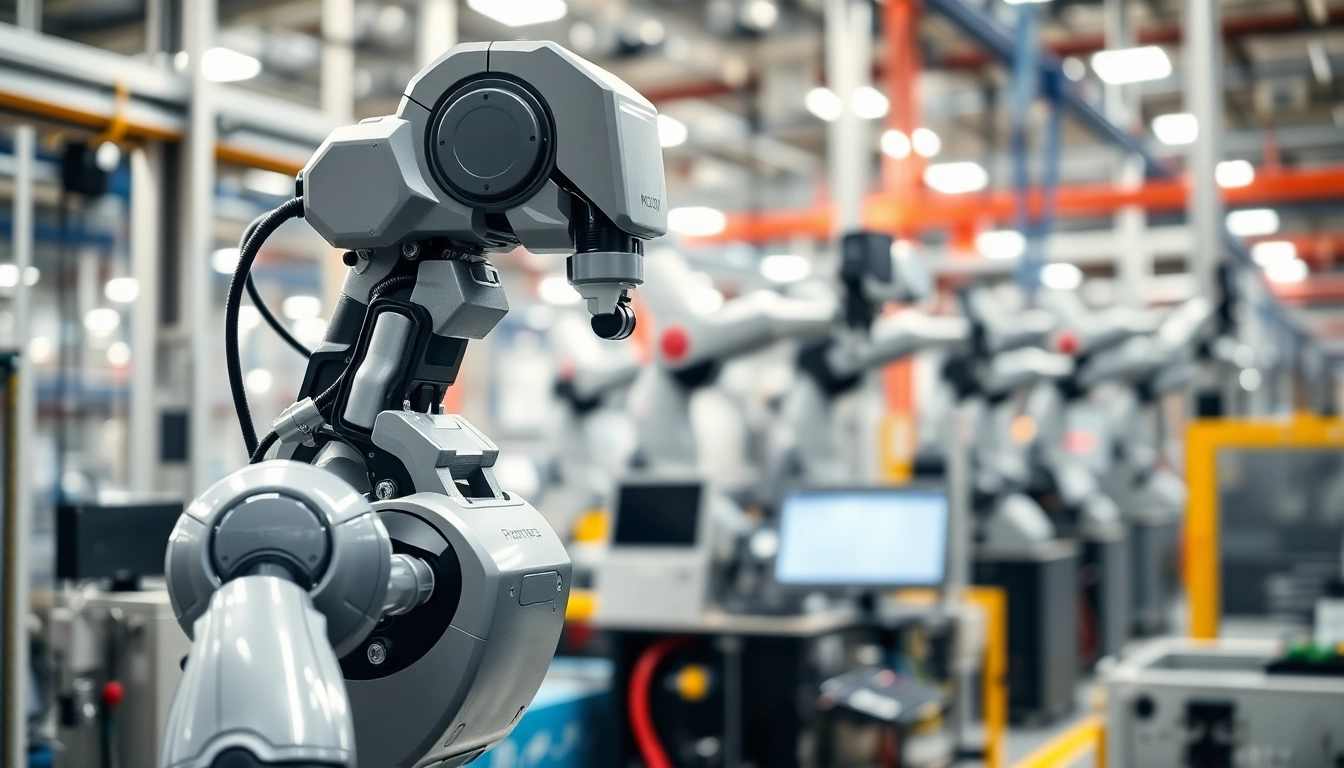

Understanding Injection Robots

What is an Injection Robot?

Injection robots are automated systems specifically designed to handle tasks involved in the injection molding process, an essential operation in the manufacturing of plastic products. These robots perform a variety of functions, from loading raw materials into the injection molding machine to removing finished parts and packaging them for storage or shipment. By integrating smart robotics with injection molding, manufacturers can achieve higher levels of precision, quality, and efficiency in their production lines. The precision and reliability of an Injection Robot make it an invaluable asset to modern manufacturing.

Key Components of Injection Robots

Understanding the key components of injection robots is crucial for manufacturers seeking to implement these systems. The primary elements include:

- Manipulator Arm: The arm is often articulated, allowing for a range of motion that facilitates the handling of heavy or awkwardly shaped parts.

- End Effector: This is the tool at the end of the arm, specifically designed for grasping and manipulating the molded parts.

- Control System: An advanced control system enables the robot to perform complex tasks and integrations seamlessly.

- Sensors: Sensors are critical for providing feedback about the robot’s operations, detecting parts, and ensuring proper handling during the molding process.

- Power Supply: A reliable power source is essential for ensuring that the robot functions without interruptions.

The Science Behind Injection Molding

Injection molding is a manufacturing process used to create parts by injecting molten material into a mold. The process consists of several key stages:

- Material Loading: Raw plastic resin is fed into a heated barrel, where it is melted.

- Injection: The molten plastic is injected into a mold at high pressure.

- Cooling: The injected material is allowed to cool and solidify in the mold.

- Ejection: The completed part is ejected from the mold, ready for inspection or further processing.

This efficient process, when combined with the operation of injection robots, allows manufacturers to produce high volumes of precise parts quickly and at a lower cost.

Advantages of Injection Robots

Efficiency and Speed

One of the primary advantages of injection robots is their ability to significantly increase operational efficiency and speed. Robots can operate continuously and can execute tasks faster than human operators while maintaining consistency. For instance, while a manual process may take several minutes to complete, an injection robot can often perform the same task in a matter of seconds. This enhancement not only decreases cycle times but also increases the overall production output, allowing manufacturers to meet rising market demands effectively.

Cost-Effectiveness in Production

Integrating injection robots can lead to substantial cost savings in production. The initial investment in automation may seem daunting, but the long-term savings in labor costs, material waste, and energy efficiency can be significant. Robots reduce the likelihood of errors that lead to scrap waste, thereby maximizing material usage. Additionally, they minimize overtime labor costs by efficiently handling peak production loads, facilitating a faster return on investment.

Improved Precision and Quality Control

Precision is paramount in manufacturing, particularly in the injection molding process. Injection robots offer superior accuracy in part handling and placement, which translates to improved product quality. The repeatability of robotic actions ensures that each part is produced according to exact specifications, leading to reduced defects and higher quality outcomes. This precision allows manufacturers to confidently scale their operations while maintaining brand reputation for quality.

Implementing Injection Robots in Your Facility

Assessment of Manufacturing Needs

Before implementing injection robots, it is essential to assess specific manufacturing needs. This assessment includes analyzing current processes, identifying pain points, and determining where automation could provide the most value. Consider factors such as production volume, the complexity of tasks, and existing machinery that robots will integrate with. Conducting a thorough evaluation helps prioritize investments and develop a clear action plan for integration.

Choosing the Right Injection Robot

Choosing the right injection robot depends on several factors, including the size and complexity of the molds being used, production speed requirements, and the types of materials being processed. Robotic solutions range from simple, articulated arms to complex multi-axis systems with varying payload capacities. It is crucial to partner with reputable suppliers who can provide insights into best-fit robots tailored to specific use cases, ensuring optimal productivity and operational efficiency.

Integrating Robots into Existing Systems

Integrating injection robots into existing production systems involves several key considerations:

- Compatibility: Ensure that the chosen robots are compatible with existing equipment and software.

- Scheduling: Plan the integration during downtime or in phases to minimize disruptions to production.

- Testing: Conduct thorough testing of the integrated systems to verify functionality and safety.

- Feedback and Adjustment: Gather data and feedback during initial operation to make necessary adjustments for optimal performance.

Challenges and Solutions with Injection Robots

Common Challenges in Automation

While the advantages of injection robots are substantial, there are challenges associated with their implementation. Common issues include:

- Initial Costs: The upfront investment in robotic technology can be significant, prompting concerns regarding return on investment.

- Integration Difficulties: Ensuring seamless communication between robotic systems and existing infrastructure can present challenges.

- Employee Resistance: Some employees may resist automation due to perceived threats to job security.

Addressing these challenges involves providing clear communication, demonstrating the benefits of robotics, and offering training to upskill existing staff.

Effective Maintenance Practices

Maintenance is a critical factor in the longevity and effectiveness of injection robots. Implementing a proactive maintenance schedule can help prevent costly downtime and extend the life of robotic systems. Best practices include:

- Regular inspections of all moving parts to identify wear and tear.

- Keeping robotic software updated to ensure optimal performance and security.

- Documenting maintenance procedures and repairs to build a comprehensive operational history.

By establishing a strong maintenance regime, producers can ensure their robots operate at peak efficiency, minimizing disruptions to production.

Training Employees for Robotic Operations

Employee training is essential for successful robotic integration. Training programs should focus on both operational and troubleshooting aspects of injection robots. Offer hands-on training sessions to familiarize employees with new technology and procedures. Creating an environment that encourages upskilling allows workers to feel valued and reduces resistance to automation. When employees understand how to work alongside robots, they are more likely to embrace technology and its benefits.

Future Trends in Injection Robotics

Technological Advancements on the Horizon

As technology continues to advance, the field of injection robotics is experiencing significant changes. Notable trends include:

- Increased Use of Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, allowing for greater flexibility in manufacturing.

- Enhanced Sensory and AI Capabilities: Future robots will utilize advanced sensors and AI to enhance decision-making and adaptability in dynamic environments.

- 3D Printing Integration: The convergence of injection molding and 3D printing technology will lead to more customizable manufacturing solutions.

Staying abreast of these technological advancements can provide a competitive edge for manufacturers looking to optimize their processes and offerings.

The Role of AI in Injection Robotics

Artificial intelligence is becoming increasingly prevalent in injection robotics, enabling systems to learn from operational data and improve over time. AI can facilitate predictive maintenance, allowing for timely repairs before faults arise, enhance quality control through real-time monitoring of production processes, and optimize the handling and logistics of parts. By leveraging AI, manufacturers can achieve higher efficiency levels and ensure a robust production process.

Industry Case Studies and Success Stories

Several industries have successfully implemented injection robots, showcasing the transformative impact of automation. One notable case involves a large automotive manufacturer that adopted injection robotics to streamline the production of interior plastic components. By implementing robots in their injection molding processes, they achieved a 30% increase in production efficiency while significantly reducing defect rates.

Another example is in the consumer goods sector. A company that switched to robotic systems in their packaging line reported a 40% reduction in labor costs alongside a 25% improvement in overall product quality. These case studies illustrate how businesses can not only survive but thrive in an increasingly automated world.