Introduction to das 142

Definition and Overview

das 142 is a standardized framework primarily utilized within various engineering disciplines for ensuring quality, reliability, and safety in both design and construction processes. This comprehensive standard encompasses a wide range of parameters that guide professionals in adopting best practices that enhance overall project outcomes. By adhering to das 142, organizations can maintain structural integrity while optimizing workflows and minimizing resource expenditure.

Historical Context

The genesis of das 142 can be traced back to the evolution of engineering standards aimed at addressing common challenges faced in construction and manufacturing. Initially developed in response to the increasing complexity of engineering projects, das 142 has undergone numerous revisions to adapt to technological advancements and industry demands. The historical journey of das 142 reflects its commitment to facilitating safer and more efficient engineering practices, particularly as the industry began to adopt more integrated approaches to project management.

Importance in Modern Engineering

In the contemporary engineering landscape, das 142 stands as a cornerstone for establishing frameworks that prioritize safety and quality assurance. It provides a solid foundation for engineers to develop innovative solutions across various sectors, including construction, manufacturing, and infrastructure. The standard not only supports compliance with regulatory requirements but also serves as a benchmark for performance evaluation in projects of all scales. das 142 not only promotes a culture of safety but also drives continuous improvement through structured feedback mechanisms.

Technical Specifications of das 142

Key Features and Attributes

das 142 encompasses a comprehensive set of features explicitly designed to facilitate precision in engineering practices. Key attributes include:

- Rigorous Quality Requirements: Specifications that necessitate stringent quality assurance protocols throughout the engineering lifecycle.

- Adaptability: The standard is structured to be flexible enough to cater to diverse engineering applications and industry requirements.

- Clarity in Guidelines: Well-defined procedures and expectations for compliance help in minimizing ambiguities that may arise during the project execution phase.

- Risk Management Tools: Integrated methodologies for assessing, managing, and mitigating risks associated with engineering projects.

Standards and Compliance

To maintain validity and relevance, das 142 adheres to international standards that govern various engineering disciplines. Compliance with these standards ensures that engineering entities execute their responsibilities in line with recognized best practices, thus fostering an environment conducive to innovation and efficiency. Organizations pursuing das 142 compliance must stay abreast of periodic updates to the standards, ensuring that their processes remain aligned with the latest requirements and technological developments.

Variations and Modifications

Over time and through practical application, variations of das 142 have emerged to suit niche requirements within specific industries. These modifications facilitate the implementation of the standard in settings where unique challenges abound. For instance, adaptations may include specialized guidelines for complex structural designs or even variations tailored for multidisciplinary collaborative environments. By understanding and applying these variations, engineering professionals can ensure more effective results and adaptation to their specific operational challenges.

Applications of das 142 in Various Industries

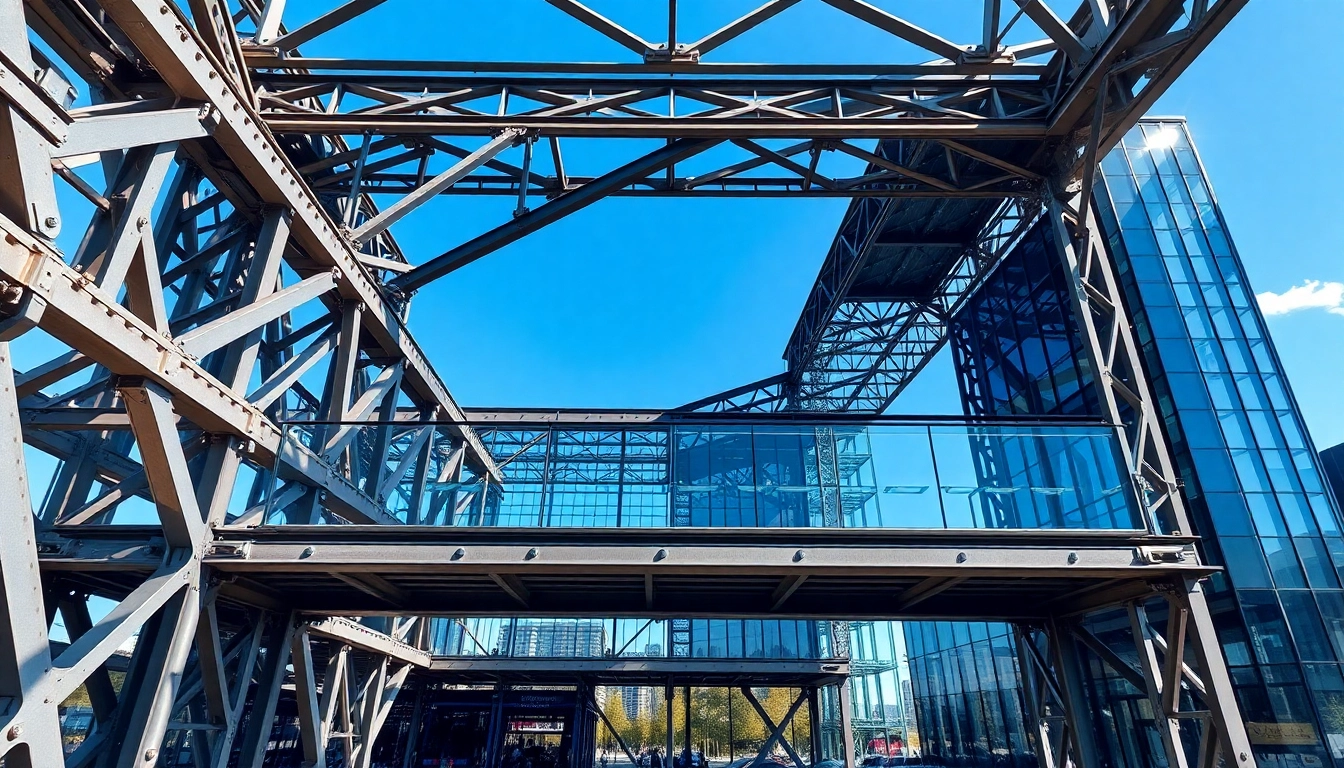

Construction and Architecture

In the construction and architecture sectors, das 142 serves as a pivotal reference point for developing safe, durable structures. By integrating das 142 guidelines into project workflows, architectural teams can ensure that their designs not only meet aesthetic criteria but also comply with safety standards. These applications may involve stress testing materials, validating design integrity under various load conditions, and employing comprehensive analytics to optimize the use of resources.

Manufacturing Processes

The application of das 142 within manufacturing processes enhances operational efficiency and product quality. In streamlined production environments, adherence to das 142 enables manufacturers to implement robust quality control measures and foster a culture of accountability. These processes might include systematic audits, performance evaluations of machinery, and lifecycle assessments of products, all contributing to minimizing defects and maximizing output.

Innovations and Future Trends

The future of das 142 is intertwined with advancements in technology and the global push for sustainability. Emerging trends involve the integration of intelligent systems and automation into engineering practices. Innovations such as artificial intelligence and data analytics are anticipated to further enhance compliance with das 142 by providing real-time monitoring and predictive insights that can prevent lapses in quality and safety. As these technologies evolve, so will the implications for das 142, ensuring its continual relevance and application in modern engineering.

Challenges Encountered with das 142

Common Misconceptions

Despite its widespread recognition, several misconceptions about das 142 hinder its full adoption. A common misunderstanding is the belief that compliance with das 142 is overly bureaucratic and stifles creativity. In reality, das 142 provides a structured approach that fosters innovation by emphasizing meticulous planning and risk assessment. Recognizing that das 142 is designed to enhance—not constrain—project outcomes is essential for organizations seeking to leverage its benefits effectively.

Implementation Hurdles

Implementing das 142 can present several challenges, especially for organizations unfamiliar with the standard. Common hurdles include a lack of in-house expertise, inadequate training for personnel, and resistance to change among established workflows. To overcome these obstacles, organizations must invest in training programs and workshops that familiarize team members with das 142 principles. Furthermore, engaging leadership in championing the adoption of das 142 can help cultivate an environment where adherence to the standard is viewed as an opportunity for improvement rather than a burden.

Mitigating Risks and Ensuring Compliance

Ensuring compliance with das 142 requires a proactive approach to risk management. Organizations can mitigate risks by conducting frequent assessments to determine areas of non-compliance or potential failure points. Implementing a feedback loop that allows for continuous improvement can also enhance adherence to das 142. Regular audits and performance evaluations, coupled with corrective action plans, will help organizations maintain statutory compliance and promote overall operational excellence.

Measuring Success with das 142

Performance Metrics to Consider

Measuring the success of initiatives that employ das 142 necessitates the establishment of clear performance metrics. Key indicators may include:

- Compliance Rate: The percentage of projects meeting das 142 standards.

- Defect Rates: The frequency and severity of safety or quality defects post-implementation.

- Time to Completion: The duration taken to achieve project milestones compared to benchmarks.

- Cost Variance: The difference between estimated and actual project costs, reflecting budget management effectiveness.

Case Studies and Examples

Real-world case studies exemplifying the successful application of das 142 can be invaluable for understanding its impact. For instance, a construction firm that integrated das 142 into its project management practices reported a 20% reduction in structural failures due to enhanced quality control measures. Another engineering company adopting das 142 experienced a 15% reduction in project timelines thanks to improved compliance and streamlined processes. These examples highlight the diverse benefits of implementing das 142 within various workflows and project types.

Evaluating Long-Term Benefits

The long-term benefits of adhering to das 142 can be substantial. Organizations often find that early investments in compliance result in reduced lifecycle costs and increased client satisfaction. By fostering a culture centered around das 142, organizations can not only ensure safety and quality but also promote innovation and resilience against future engineering challenges. The continued relevance of das 142 in advancing industry standards is testament to its strategic importance in nurturing a robust engineering ecosystem.